Professor John Quelch, the co-founder and member of Board of Director of Boston Global Forum, is a distinguished Professor of Business Administration, who has has recently authored a Harvard Business School case study on the tragic Rana Plaza garment factory collapse that claimed 1127 lives on April 24, 2013. The case study offers an insightful snapshot of the reform analysis needed in the garment manufacturing industry. He currently leads the discussion on Boston Global Forum on this globally challenging complex issue.

His study recognizes that the Bangladeshi parliament, cornered by domestic and international pressure following this tragedy, ratified changes to their Labor Acts earlier this summer. The case study examines the systemic failure of government protection of human rights for garment factory employees, extols the need for adherence to the principles of socially responsible manufacturing and provides an overview of the cooperation pact signed by 80 global retailers and two labor unions to improve working conditions in Bangladesh.

The Bangladesh Garment Industry

The Bangladesh Garment Industry was a major force in its economy, employed about 3.6 million people or roughly 2% of the population. Its export value was worth $21 billion in 2012, and accounted for 13% of GDP in 2011. Nearly 90% of garments produced in Bangladesh were exported to the U.S, Europe and Canada. In 2012, the US alone received $4.9 billion worth of garment exports from Bangladesh. Low cost production and large capacity were key incentives for multinational corporations (MNCs) to produce garments in Bangladesh. Combined labor cost differentials were expected to help Bangladesh’s garment industry to reach $30 billion by 2015.

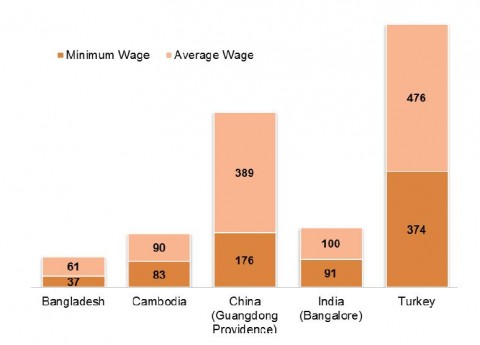

Garment Industry Monthly and Minimum Wages by Country

On April 24, 2013, the nine-storey Rana Plaza building collapsed, killing 1,100 workers and injuring 2,500 more. The disaster might be prevented due to the fact that there was a warning of the building unsafe and recommendation that the worker be evacuated by an engineer to the building owner. However, it was passed over in silence, and by the declaration of a local government official that the building was safe.

And MNCs’ response….

After the collapse, MNCs with operations in Bangladesh had several options on how to respond to the Rana Plaza tragedy.

MNCS were not directly responsible for the disaster, and many MNCS that had already been conducting factory inspections (like Wal Mart) would continue to do business as usual, and retain private records of infractions with no obligations to alert workers of safety hazards.

Some MNCS decided to shift all of its production away from Bangladesh to other , lower risk countries (like Disney corporation) in order to lessen the risk of negative press or irresponsible labor practices tainting the brand.

The other MNCs could decide to remain its manufacture in Bangladesh and partner with factories to improve safety conditions in the garment industry.